Inventor Presentations

Autodesk has done an impressive job within Inventor Presentations by integrating the storyboard, snapshots, and other improvements. Creating views of assemblies is quick and painless. The views also flow into drawings with parts lists and made it easier to communicate manufacturing and assembly details to the shop floor.

Building an online customer portal is one of the most recent tasks added to my duties as a Technical Services Manager. This portal is to be something that the customer logs into and sees their equipment, the equipment status, operator manuals, service guides, service bulletins, and other information. Each piece is to contain the option to order parts online. By building, this isn’t doing the actual development, but obtaining the technology and tying it all together to make the “magic” happen.

A major component of this solution is utilizing the existing CAD data generated by Autodesk Inventor. What has become very clear in the process is Inventor Presentations are very good at generating views and exploded presentations of assemblies. In fact, it was better than any other tech we looked at, and this included technology by PTC and Siemens.

For as great as this environment is, I feel it is missing some key features and functionality. These additions to Inventor Presentations would expand Inventor’s place in the ecosphere, branching out from a manufacturing detailing tool, into a robust technical communication juggernaut.

Bill of Materials

I read a lot about manufacturing, as not only is it interesting but I’m living it day-in and day out. For manufacturers, the trends show the transition of the service aftermarket from a cost center to a revenue and profit generating portion of the business. However, many manufacturers have a disconnect between engineering/manufacturing and the service departments. This disconnect directly impacts revenue (service) and weakens the reputation of the organization.

I want to transform the Inventor Presentation environment into a powerful manufacturing and after-manufacturing communication tool. This starts with a specific bill of materials in the presentation, which I am labeling as the PBOM (Presentation BOM). In the new PBOM, we’d transform the manufacturing BOM into a tool utilized by manufacturing and by areas outside manufacturing (including service). We’d be able to rearrange, promote, demote, and group components into subassemblies. It would capture import information like replacements, super sessions, and suggested replacements. It would allow for the creation of spare parts lists and parts catalogs

Parts Catalogs

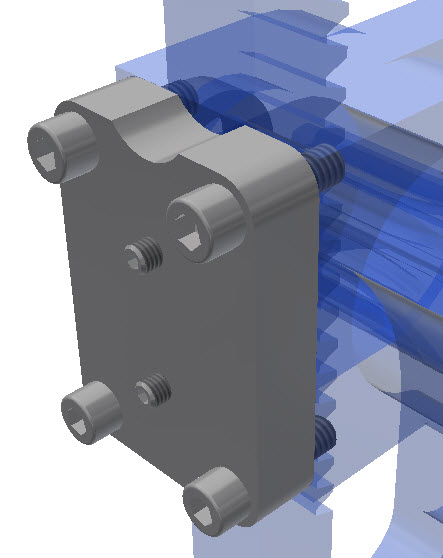

For this scenario, let’s use the Arbor Press as an example. We build the components, add the required meta-data (iProperties), and complete the assembly. The Bill of Materials now represents how I’m going to manufacture the assembly… perfect.

However, how we sell parts to our customers does not always align with how it is manufactured. In many cases, the customer buys replacement kit type groups of components. With the Arbor Press let’s say we know that when buying a new FACE PLATE that they will typically wreck the bolts during disassembly due to the Loctite added during assembly. In this case, we want to sell the customer a single Face Plate Replacement Kit, that contains the Face Plate, and the four bolts.

Service Bill of Materials

Additionally, disassembly of the components for service does not always match manufacturing. We have situations where we want to hide parts from the BOM, yet keeping them visually available. We also want to present the BOM as a list of items that are involved in the step. Think of this as the Ikea style instructions but in reverse order. Using the new PBOM I’d be able to hide and rearrange the BOM for the active storyboard.

With the Arbor Press again, with disassembly of the handle, we do not need to show the LEVER ARM and HANDLE CAPS. We want these components visible but not listed in the BOM as they just automatically are assumed to be removed during disassembly.

The PBOM

My PBOM, the facts:

- A Bill of Materials per Storyboard

- Ability to rearrange the order of components, including demoting and promoting into and out of subassemblies

- Option to add new components: virtual parts and new subassemblies

- Filters to show quantities for just what is visible in the active storyboard

- Tag parts as suggestions (upsell, down sell, superseded, obsolete, etc)

- When creating drawings, the option to select the assembly BOM or the views Storyboard PBOM

If Autodesk needs an example of how this could work with Inventor Presentations they don’t need to look very far. Within AutoCAD Mechanical you add multiple BOMs either by starting from scratch and adding the desired components or by selecting a title block and it selects the components contained within the title blocks region. This workflow is not much different than my proposed BOM per storyboard.

In this example, the drawing contains two BOMs. One for the entire assembly and then one for the specific border. For dramatic effect, I overwrote the descriptions of the parts, hence why they show in blue. It provides a lot of flexibility, yet eloquently, and easy to manage.

Challenges

This new functionality is not without its challenges.

Updates – how will changes to the assembly impact the pPBOM? So a workflow for dealing with updates to the assembly needs to be defined. My thought is that it works like view representations.

My thought is that it works like View Representations. When overriding a component in the pBOM you are prompted to either break the association or to override the link. By breaking the link, any change to the assembly BOM will not apply to the pBOM. This creates a “free reign” type environment, allowing you to manipulate the PBOM however you see fit. By selecting Override only that component is allowed to be manipulated. The other components remain linked to the assembly’s BOM. The PBOM would require visual indication to identify parts linked to the assembly BOM and those that are not. This would also require some type of update process to update the PBOM to incorporate changes to the assembly BOM.

Vault Items – Vault Professional would need updates to work with the new PBOMs. I’m torn between Inventor Presentations getting their own item (and BOM) or the existing item getting additional views to view the PBOMS.

In Summary

I created an idea in the Inventor Ideastation and would appreciate your upvote. I cannot imagine are the only manufacturers who could utilize this functionality.

I see this as win-win:

- a win for customers who are able to extend their workflows past manufacturing

- a win for Autodesk, as none of their competition includes this functionality without add-ons and/or additional software

What’s Next?

This is the first part of my ideas. In the next post, I’ll explore my ideas for 3D annotations, visualizations, and the ability to insert symbols.

Feature Image “Presentation Room” by Babak Farrokhi