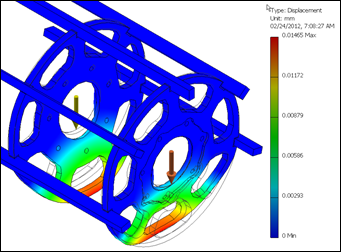

While reviewing the stability of this chassis design, I needed to over develop the loads in order to provide some non-linear safety buffering. The design employs two of these support cages at a time, for a total of 4 support beams. I have 6000 N of static load total, and I wanted to start by ensuring that each support could carry the entire load. This way when i get into dynamic analysis, I won’t come up short. It’s easier to remove materials later than to have to fix critical errors on the back end.

Each Load is the Sum of Applied Forces

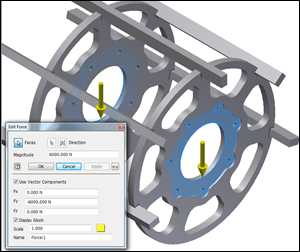

What I wanted to point out is that each static stress analysis load in Inventor is the sum of the applied forces, meaning that these are ‘shared’. When you pick two faces during the load assignment, Inventor splits the load over the number of faces selected. In this example, each face is only experiencing 3000 N.

This is really helpful when you know what your sum of Force x and sum of Force y values are, and need to apply these over all affected surfaces.

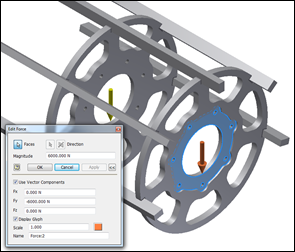

In my case, I wanted to see what the effects of the total load would be upon each face. What I did was apply separate loads to each, using the same load of 6000 N. See the difference in displacement.

Each has a great use, just be aware of these when you are applying your loads. More importantly, always evaluate your results with some comparisons. This will help you spot mistakes in the simulated environment setup, long before the physical model test comparisons.