Recently I visited Solid Edge University 2014, and was permitted access to Solid Edge, Siemens PLM leadership, strategies, development team, and the people that use the software to develop wonderful machinery and products. This article will discuss the nature of the company, and look at its position in the rapidly changing CAD design market. I will also try to point out the potential roadblocks that the company may face in the changing market.

Brief History

The Solid Edge CAD solid modeling software has been in use since 1996, when it was developed by Intergraph. After a purchase and kernel change 2 years later, UGS Corp continued to develop the software until ultimately being purchased by Siemens AG Automation & Drives Division in 2007. The division was renamed to Siemens PLM Software as we now know it. Almost immediately following the renaming, Synchronous technology was introduced, marking a significant change in the 3D CAD software’s profile.

This year the Solid Edge team released version ST7, marking the 7th year that synchronous technology has been offered to its customers and marks the product’s 27th release.

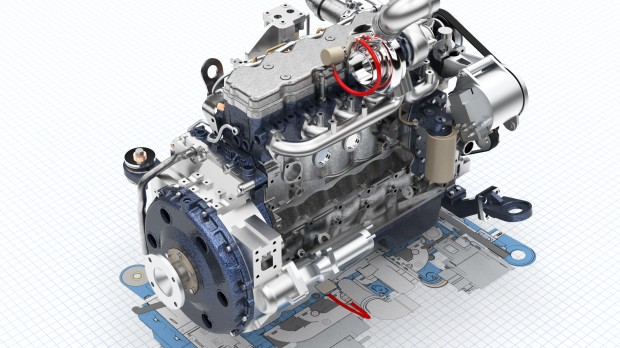

Solid Edge, Synchronous Technology, and Model Based Definition

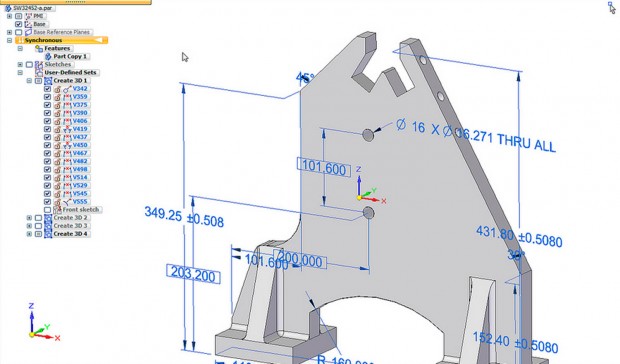

Synchronous technology was conceived as a new way to work with 3D CAD model data, one that left so many awkward methodologies behind. The software can read almost any 3D CAD model, and accurately alter the model features and definition as if the model data was developed in Solid Edge all along. The software technology has progressed to the point where intended geometric relationships such as parallelism, concentricity, mirrored features and patterns are automatically recognized and maintained as the user desires. The product can be used in both the traditional ordered method of modeling or in Synchronous mode, and allows users to toggle between these, permitting additional flexibility.

Additionally, the software automatically embeds user-applied dimensional constraints into the Model Based Definition (MBD) which appear as Product Manufacturing Instruction (PMI) tags, and permits the addition of full Geometric Dimensioning and Tolerancing (GD&T). This is all accomplished in a fluid manner and offers 2 key benefits:

- Full adoption of ever increasing dependency on MBD and PMI in the industry

- PMI can be automatically extracted for use in the 2D drawing (should drawings be needed) and reduces the need for the technician to dimension features in the drawing itself, which focuses the GD&T on the features as they are designed, and not on paper after the fact.

End User Adoption

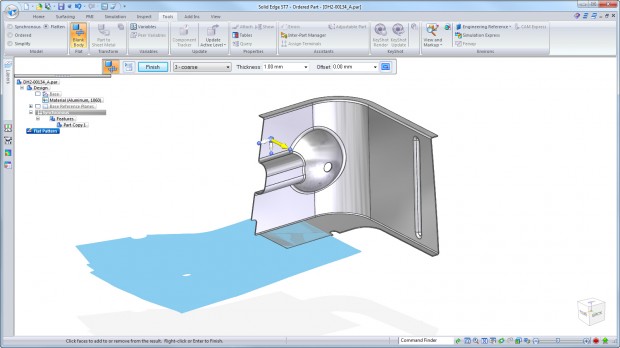

Solid Edge is known for being an industrial design product, lending itself very well to the processes surrounding machine manufacturing and sheet metal structure fabrication. It is generally acknowledged to be stable and competitive in the arenas where adoption is the greatest.

While Synchronous technology has been available for a few years now, a wide cross section of the user base agree that Solid Edge ST5 was a significant release in stability and functionality. Even so, there appears to be a large percentage of users that have never adopted this technology. Preferring to continue to upgrade their Solid Edge software, but operate in the traditional ordered manner. This situation appears to be obvious to the leadership at Solid Edge, as Karsten Newbury, Senior Vice President and General Manager, Mainstream Engineering Software at Siemens, went on stage at Solid Edge University and said, “We spend too much time thinking about how to design something, and not enough time thinking about the design”.

My interviews and observations indicate that:

- 75% of the user base were 8-10 year + veterans

- 15% were new to Solid Edge, 1 year or less experience

- 10% remainder

Customer Satisfaction

Short of Amazon.com, Solid Edge has the best customer satisfaction I have ever found. This ST7 release was proudly hailed in with the acknowledgement that it satisfied over 1300 customer requests. This demonstrates that the company clearly knows its customers are keenly watching their support and end-user commitment.

The customer base appears to be very cad-to-manufacturing oriented. Most users I have talked with are one step away from the manufacturing processes, and the majority simply wanted to get from “point A” to “point B”, and not really anything more. “Does this change help me get my job done…today…now?”

Last year I spent time meeting a wide variety of users that all seemed to feel the same way; The company listened to their desires, responds appropriately to get them exactly what was asked for, and the customers believed that the company truly cared about what each user needed.

Interviewing Transitioning Users

This year I found two groups. That first satisfied group of users with the same enthusiasm about the product, as well as a group of new users that had previously used SolidWorks.

In many of the cases where transitions had occurred, Solid Edge was adopted in order to access the manufacturing process-specific features that other CAD software did not provide. This was of significant enough value to these companies to overlook the CAD platform transition pain, and UI that they had grown accustomed to. The ratio of transitioning users I was able to meet would not signify a trend, but some of their comments were consistent: “Certain tasks remain much simpler with SolidWorks, however the ST7 release should return a good amount of our lost functionality”.

When I asked about the specifics I also found a surprising number had not upgraded Solid Edge recently, thus the reason for many of the aforesaid transition woes. Financial constraints seemed to be the overwhelming cause, waiting for a significant quantity of valuable enhancements to Solid Edge (individual perspective) before making another upgrade. There was a lot of talk about ST7, and many of these companies indicated that they intended to upgrade after its release.

Future for the Company

I find Solid Edge in an odd spot. On one hand Synchronous technology and the user-specified product enhancements offer very well adapted CAD tools to the manufacturing industry. On the other, the product may not include certain aspects that some other vendors have moved towards. These include workflows that may not be used by many in traditional manufacturing spaces, as well as UI variations specifically targeted towards the freshman user group, whose time has been consumed and heavily influenced by easy-to-use and simplified software UI or more modern CAD interfaces in rival products experienced during their education.

This presents the question about expanded sales and freshman user adoption. What happens when the existing, aging workforce passes on? What is the company doing to engage and attract new users and sales?

Solid Edge has not furnished anything specific about this question, but was keenly interested in what people had to say about it.

The new approaches to sales and development that the company has started may be an indication of what direction they are trying to go.

- Added monthly subscriptions

- Added academic licensing

- Support and sales in 22 countries

- Online store with 3rd party apps and their development API

Additional factors that are attractive include:

- New enhancements included in ST6 and ST7 make Solid Edge far more competitive among the other CAD vendors in wider circles

- Solid Edge’s ongoing support of PMI does trend well with companies who, like Boeing and increasingly their sub-contractors, no longer ship 2D drawings, preferring to constrain all the deliverable data to the model file, including the PMI data instructions.

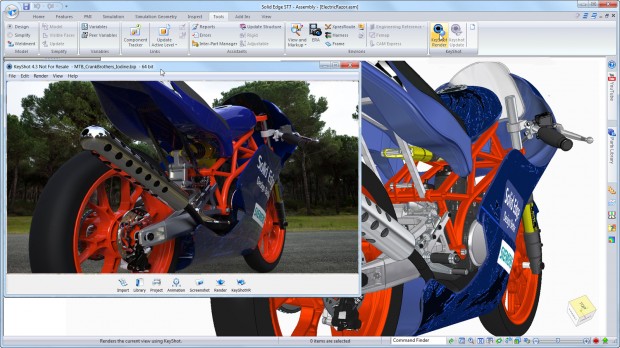

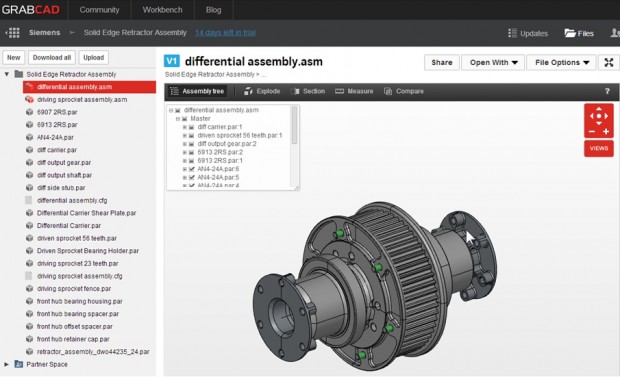

- Solid Edge’s tight partnerships with vendors that support advanced sheet metal, visualization, manufacturing, and data management strategies is quite progressive (such as CamWorks, MACsheet, GrabCAD, KeyShot, etc.)

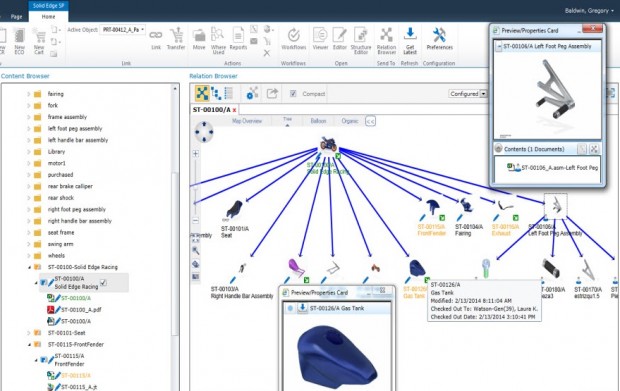

Close 3rd Party Developer Relationships and Data Management

Another noticeable difference that the company seems to have adopted is their close 3rd Party vendor relationships, and their willingness to allow users to choose whichever solution meets their needs, even when the solution is competing with their own. One big example is Solid Edge SP, their recently developed Sharepoint based data management solution. The company seemed to be happy to offer different management solutions to their customers to choose from, almost striving to ensure every reasonable solution to meet their customer’s needs.

There seemed to be a very significant trend at the conference with data management. Siemens is as mentioned before strengthening their own feature packed and robust Solid Edge SP. Additionally, more 3rd party management vendors were appearing this year (all of which I interviewed were cloud based solutions). The trend I noticed at SEU is that none of these vendors were offering generic management platforms; every one including GrabCAD were well aware that if their products did not deal with Solid Edge CAD models and related workflows properly, no one would give them a second of their time.

Final Thoughts

I have become quite fond of the improvements in Solid Edge of late, and the wonderful company that:

- Is keenly focused on its customers’ needs

- Seems to operate with the philosophy that customers will upgrade when they are presented with sufficiently valuable improvements (they don’t force their customers to upgrade)

- has very pronounced customer satisfaction

- is heavily involved in industry requirements such as standards and MBD

- is improving their synchronous technology on track with their vision of leaving behind all the awkward CAD design workflows we have been tied to

My observations of the company are however a bit perplexing. I doubt anyone will argue the value and benefit of Solid Edge in the drafting and machine manufacturing spaces. Additionally, with MBD at the heart of the model, as 2D drawings decline in importance, their product will still be at the front of the pack in terms of delivering on the new industry standards, not to mention that it has been offering it to its customers longer and has more experience with it than any other competitive SMB CAD software (SolidWorks 2013 may be presenting this functionality).

There are some UI type workflows and handoffs that need to be refined in order to be competitive in the broader CAD market, one such improvement is data referencing. (Yes it’s my biggest whine; I’m writing this so I get to name mine). Users should be able to reference a dimension, an offset, etc. when needed in any space, without having to copy/paste or enter additional dialogs and the like. If features are the key focus in Solid Edge, then allow users to reference important PMI in equations by simply picking the feature and then the selecting the PMI data tags that magically appears; nothing more. When the overall issue surrounding similar needs are addressed, Solid Edge’s deep-down control of the solid model and MBD may well put them in a position to take a large chunk of small to medium sized business (SMB) CAD sales.

However, the company has acknowledged the need to address the incoming wave of CAD freshman and the new technologies that are being presented to them. Their pursuit of progressive partnerships while continuing the development of real-world manufacturing needs is quite uplifting. The cloud based collaboration that meets the new SMB needs and doesn’t detract from their existing user’s workflows is a positive step too. Getting Synchronous capability into the hands of the up-and-coming CAD users is also a good strategy, but needs more emphasis.

In the mean-time I remain quite happy with the new, much needed enhancements in ST7, and the data management and collaborative initiatives that are emerging. I am intently watching however for how Solid Edge’s upcoming strategy will unfold.

Is Solid Edge Synchronous technology good enough to allow users to “think more about their design and less about how they will design it?” To some degree yes, but it is in no way perfect. However the technology and the ST7 release do take users a long way down that newly paved road.

Disclaimer: The author attended Solid Edge University 2014 as a guest of Siemens PLM Software. No articles or endorsements were solicited in conjunction with this invitation. All images were furnished by Siemens PLM Software.