A couple of weeks ago John & I got to Interview Autodesk Product Marketing Manager, Simulation, Luke Mihelcic. Some of you will have read about Autodesk’s launch of Autodesk Flow Design. Some of you may have even seen it feature as part of the Super Bowl. I don’t know about you lot, but we were pretty impressed that Autodesk managed to feature so prominently as part of the jewel in the crown of America’s greatest past time (some might say). Luke did an incredible job of fielding alternating questions from New Zealand and Florida simultaneously, while we all had fun doing so. Anyway, let’s crack on with the goods shall we?

Note: This interview wasn’t recorded unfortunately, so Luke’s responses have been paraphrased throughout.

D&M: Why didn’t Autodesk Flow Design get a standard Autodesk Simulation name?

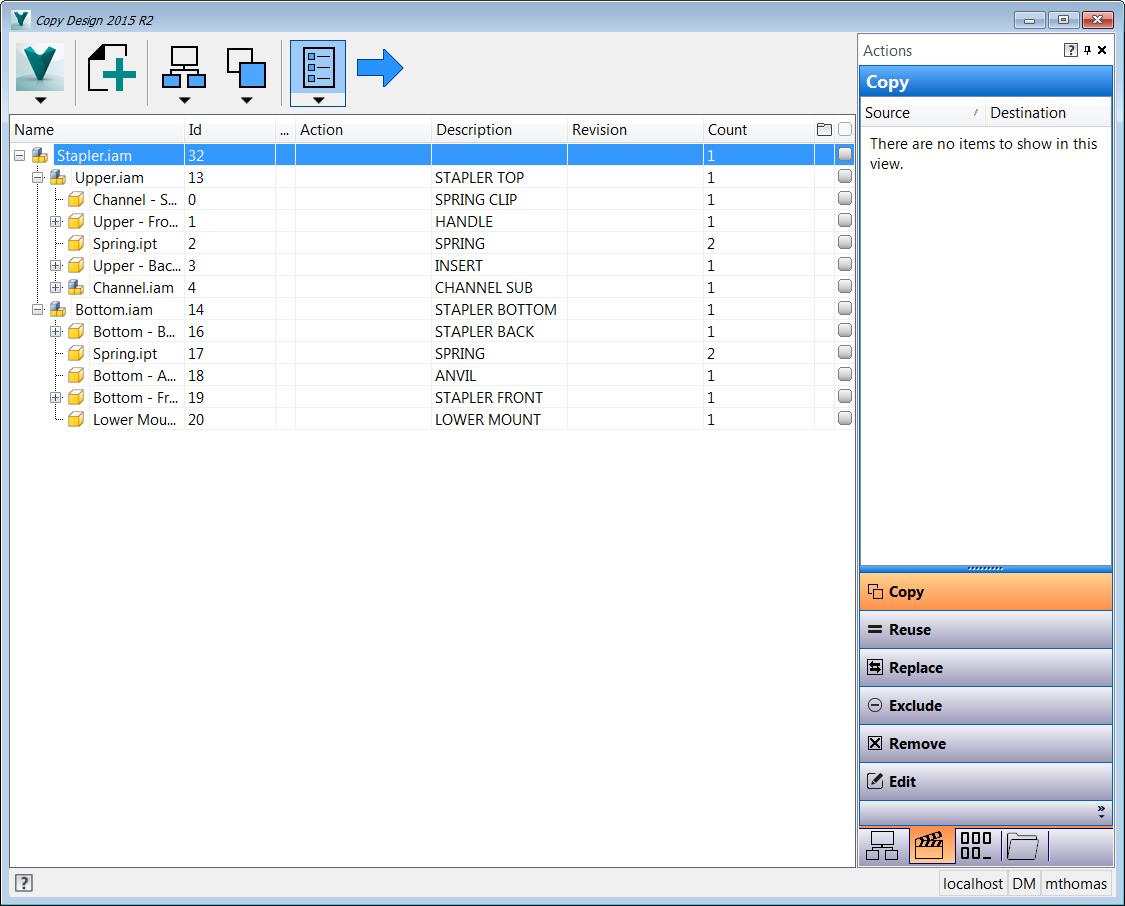

Luke: With Autodesk Flow design we are targeting the designer market, rather than the traditional simulation audience. Flow Design is very similar to Autodesk Simulation DFM (Design For Manufacturability) in the sense they are both purpose built with a narrow focus. It does one thing and does it very well. Not only do we have the standalone version, but both Inventor and Revit have Add-Ins. This introduces a familiar ease of use and level of feedback appropriate for an associate degree level individual and maybe an engineer. Additionally it’s very geometry tolerant, unlike full blown simulation tools. With this in mind it’s quite likely Flow Design will mostly be used for mechanical or architectural products. That’s why simulation isn’t in the name, it’s more about helping to guide the design & make sure the basic design specifications are being met at an early stage. I know one of the things we want to do is build purpose built tools for specific applications, so don’t be surprised if you see more purpose built tools.

D&M: Is there a cost benefit?

Luke: Cost benefit is tough to measure, but there definitely is one. For example, you currently do wind tunnel testing. Every time you do a different configuration, you are charged for that configuration. With Flow Design, however, you can reduce the number of physical wind tunnel tests by optimizing your design and possible configuration before you go to the testing facility.

In addition, you’re not doing any wind tunnel testing or conceptual design simulation. A problem with design later in the development process causes you to have to re-work it when it’s more expensive. Had you used Flow Design early in the process, however, you could have optimized the design and reduced the amount of design re-work.

D&M: Is Autodesk changing tack slightly with this? In the sense that this tool seems more appropriate for pre-design, whereas the full blown simulation tools are more appropriate for post design validation?

Luke: We’re not changing, but adding a new tactic instead. We’re trying to create a new audience since no one is creating these designer level tools.

D&M: How are you making it easier to understand the results?

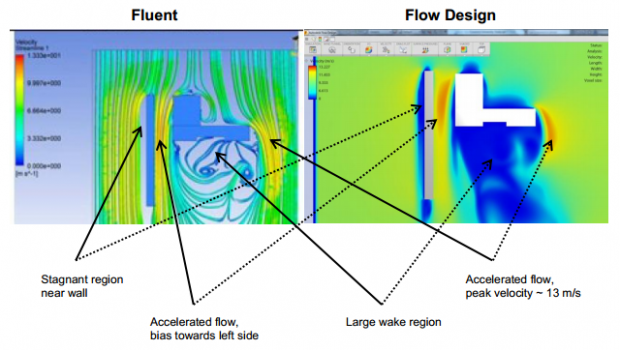

Luke: Flow design basically just gives you lift & drag results. As long as you know what they are, you can look at what those mean & look at changing the design to alter those figures. One of the most powerful aspects to Flow Design is the CAD application integration. This translates to the ability to adjust the design and receive immediate feedback. Ideally designers don’t want to wait for a simulation to run, so that feedback needs to be fast and Flow Design doesn’t disappoint. As you play around with the design and see the result of those changes, it builds your understanding of the results, it teaches you to recognise better results. So in that respect, the visuals give you the lion’s share of the feedback for those who don’t understand that as much. For example, you might want to try to limit recirculation & streamline flow etc… It’s really about the visuals, just like DFM.

D&M: This brings up the next question nicely… Is the solver desktop based?

Luke: Autodesk Flow Design is not a cloud solving tool, it runs extremely fast locally. The development team have done a lot of creative things under the hood to achieve this. In most cases the product videos on our website & around the web are showing the tool running on a standard mobile workstation!

D&M: Have you done any benchmarking of this solver against wind tunnel results?

In terms of validation documents, you can access those materials here. In addition, Luke wanted to pass along an even more detailed PDF with links to relevant information.

D&M: The validation document makes for interesting reading. It really is impressive how close Autodesk Flow Design is relative to highly respected & much more costly CFD software.

D&M: Is there any reason why this didn’t go straight onto the 360 platform?

Luke: Project Falcon was developed as an Autodesk LABS tool almost a full year before we had any cloud simulation tools. That said, we wanted to create tools that work where designers are using them now, and that is currently on the desktop. As designers and our target audience migrate to the cloud, however, we will re-evaluate how we want to deliver Flow Design.

D&M: What enhancements have been made since Project Falcon and prior to full release?

Luke: Most of the enhancements were within the User Interface. This started out as a very successful Labs project, but when people are being charged money they have difference expectations, so we added some polish to fulfil those. Performance has also been greatly improved, it’s pretty amazing seeing it running inside Autodesk Inventor. With regards to functionality, there aren’t any new tools, it’s still all about wind speed & direction.

D&M: Does it handle multi fluids? Such as water & air flow analysis for marine applications?

Luke: There have been a few requests for multi fluids. But it’s air only at the moment. The challenge with water, is most people want it to be free surface, which is a whole ‘nuther ball of wax, it really is full blown CFD. Plus it doesn’t really fit the target audience. The person wanting to do free surface simulation is probably a full blown engineer or analyst. So we probably won’t see that coming. In addition it’s purely external airflow, so it’s no good for pumps etc.

D&M: Which area do you see this specific focused approach to simulation being used next?

Luke: Designers already have crazy ‘early on’ tools already, such as the Force Effect group of applications. We really want to make sure we have the right tool, for the right person, at the right time in the design process. We have done a really good job hitting people with mid-range tools & then full on high end SIM tools with CFD & Mold Flow. We will probably start to see ‘point tools’ to address the gap between Pre-Design and Post-Design, along the lines of tools seen in Inventor Professional, DFM & Flow Design are recent examples. This is how I see the really high level general road map.

D&M: How have users reacted to the Inventor Add-in vs the standalone application?

Luke: The functionality is identical between the two. The add-in allows real-time modification, whereas the standalone application extends Flow Design out to Non Inventor and Revit users. The feedback has been hugely positive, especially in relation to how geometry tolerant it is. You just don’t have to clean up geometry, there’s no mesh for the user to deal with, and you just run your simulation.

D&M: What kind of adoption have you seen?

Luke: Well that’s to be determined. We will see more clearly once the Labs project expires.

D&M: Which industries are most prevalent?

Luke: With Autodesk Revit having an Add-In, the AEC industry can study any adverse effects of their designs. Of course there’s a lot of opportunity within the automotive industry, such as people making components and after-market parts. A lot of start companies would likely find this useful. The Morgan Motor Company is a great example of a company that could benefit in the early stages of their designs.

D&M: So what does it cost?

Luke: $35 USD per month, or $210 per annum. We’re only offering term licenses which can only be purchased on our e-store. At this stage it’s only available in English. Unfortunately there’s a technical issue preventing us from selling it in Brazil at this stage. Our team is working on resolving it ASAP.

D&M: What support is available for Flow Design?

Luke: Basic support is included which will primarily be executed via email and the Autodesk support forums.

D&M: Thank you for taking the time to talk to us Luke, as always it was a pleasure!

Design and Motion have been given access to Flow Design, so we will setup it up and take it for a spin. Keep an eye out for a post in the next couple of weeks.

To cap off this interview, take a look at Flow Design in action at Super Bowl XLVIII in the videos below:

What does everyone think about this Designer tailored approach to simulation? Let us know in the comments below.

Special thanks to the Autodesk PR team for choreographing the supporting information for this interview.

[subscribe2]